Roofing Sandwich Panels with Polyisocyanurate (PIR)

Product description

Roofing Sandwich Panels with filler (PIR) are three-layer panels with fire-resistant polyisocyanurate (PIR) insulation, manufactured using a customized PIR Premier system with the best imported components.

Becouse of their low thermal conductivity of up to (0.022 W/mK), PIR roofing sandwich panels help reduce heating and air conditioning costs.

The panels are CE marked and produced in compliance with the European EN-14509 certification, available in any RAL standard color.

Roofing sandwich panels are used for covering the roofs of buildings and structures with a roof slope of more than 7 degrees. They can also be used on roofs with a lower slope if installed “ridge down,” followed by the application of a waterproofing membrane.

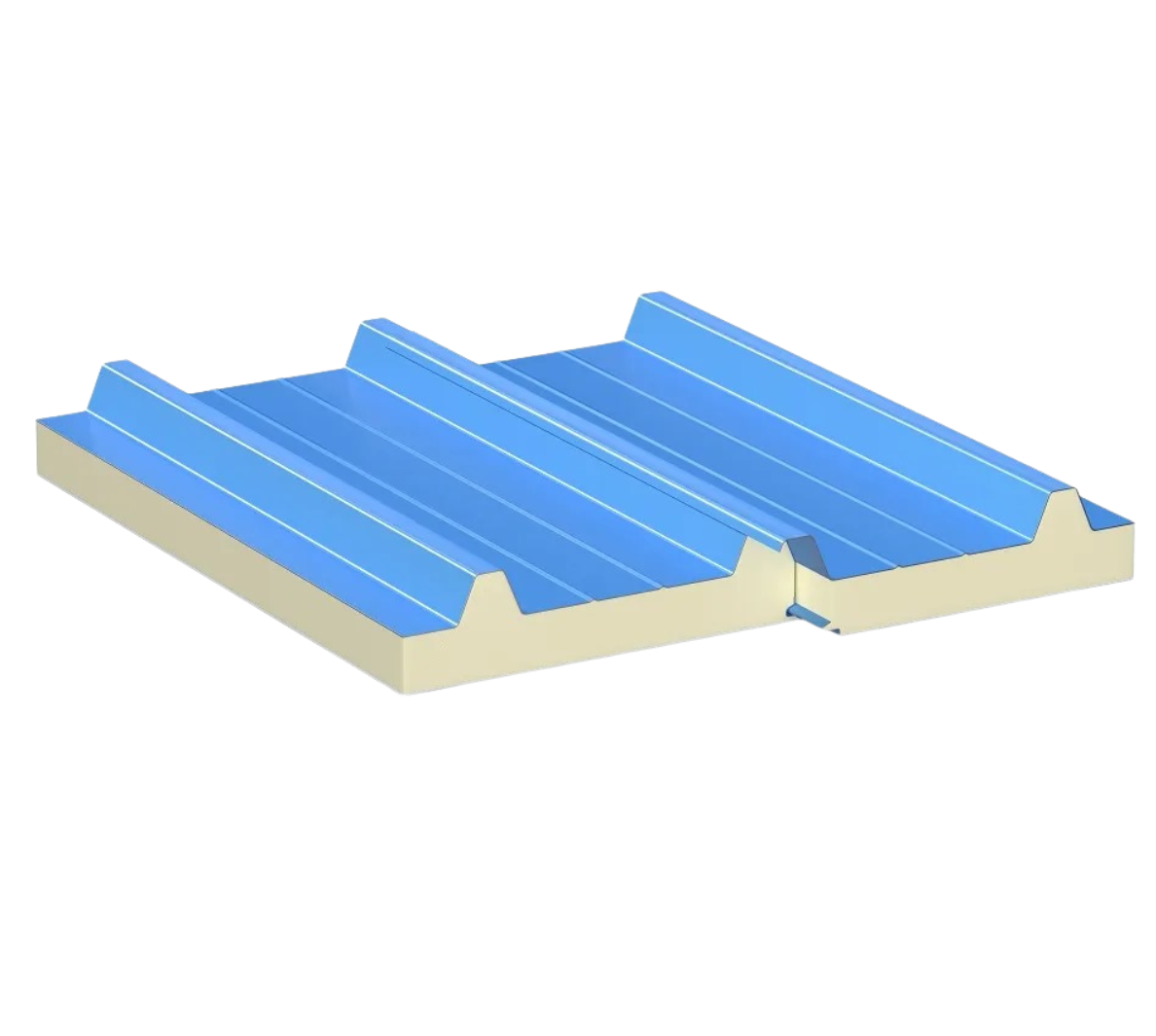

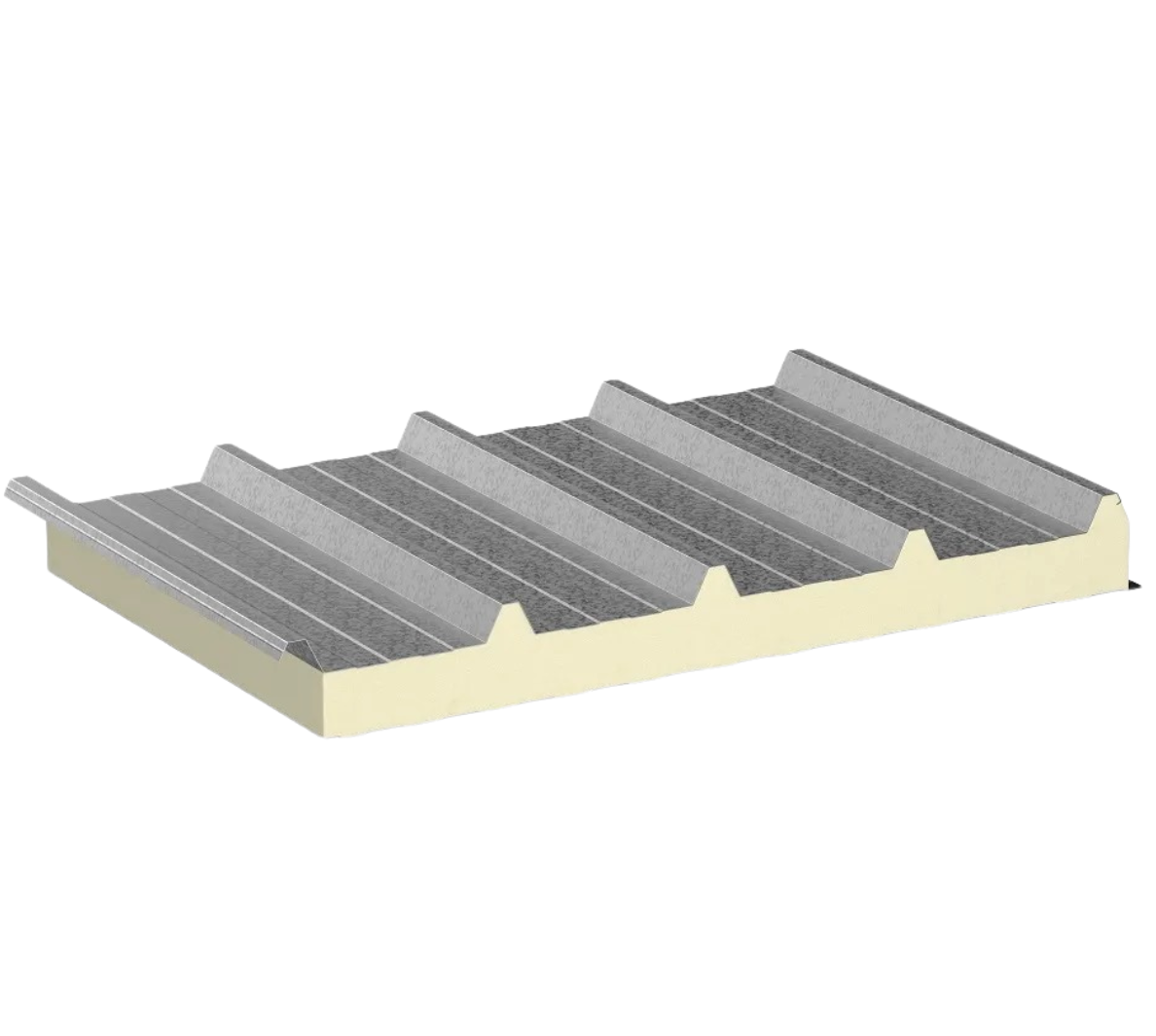

Structure of (PIR) Roofing Sandwich Panels

A drip collector integrated into the locking joint of the roofing sandwich panels collects condensate and prevents it from entering the structure. The edge of the metal sheet at the joint is bent 180 degrees, allowing installation without damaging the metal surface and providing additional rigidity to the joint.

The locking joint of the roofing sandwich panels is manufactured with high precision. Gaps of less than 0.5 mm reduce heat loss and minimize the use of installation materials during the mounting of the roofing panels. Thanks to the precise fit, there is no need to foam the joints, which speeds up the installation process. The edges of the metal sheets are embedded into the PIR layer, ensuring the strength and monolithic integrity of the structure.

The roofing sandwich panels are fixed to the building’s metal frame using self-tapping screws.

Technical characteristics

Advantages

Thermal Insulation

PIR roofing sandwich panels, with their three-layer construction and fire-resistant PIR core, provide excellent thermal insulation, while their low thermal conductivity (0.022 W/mK) helps reduce heating and cooling costs. These CE-marked and EN-14509 certified panels are durable and easy to install.

Cost-Effective

Sandwich panels are more affordable than traditional construction materials. Their finished, treated surface eliminates the need for additional facade cladding and repair work, which reduces construction costs. Additionally, the combination of energy efficiency, thermal insulation, and durability significantly lowers overall expenses during the construction process.

Fire Resistance

PIR roofing sandwich panels feature fire-resistant PIR insulation and low thermal conductivity (0.022 W/mK), ensuring energy efficiency. They are CE marked and EN-14509 certified, providing durability and safety.

Lightweight Construction

Sandwich panels are much lighter than traditional construction materials. Their lightweight nature allows for a reduction in foundation costs, as the panels can be easily installed without the need for heavy lifting equipment.

Eco-Friendly

PIR sandwich panels stand out for their energy efficiency, making them an environmentally friendly product. The materials used in their production are non-toxic and recyclable, which helps reduce waste and supports the development of sustainable construction practices.

Endurance

one of the key advantages of PIR roofing sandwich panels is their durability. They are specifically designed to withstand harsh environmental conditions, including high temperatures, strong winds, and prolonged exposure to ultraviolet radiation. The panels retain their original appearance and properties over the years.

Service process

Consultation & Planning

We calculate quantity of panels, thickness, and metal type of surface to fit your project precisely.

Production

The product is manufactured using advanced technologies, ensuring quality and durability.

Pickup & Delivery Help

Pick up from our warehouse, or we help arrange delivery if needed.