Roof sandwich panel

Product description

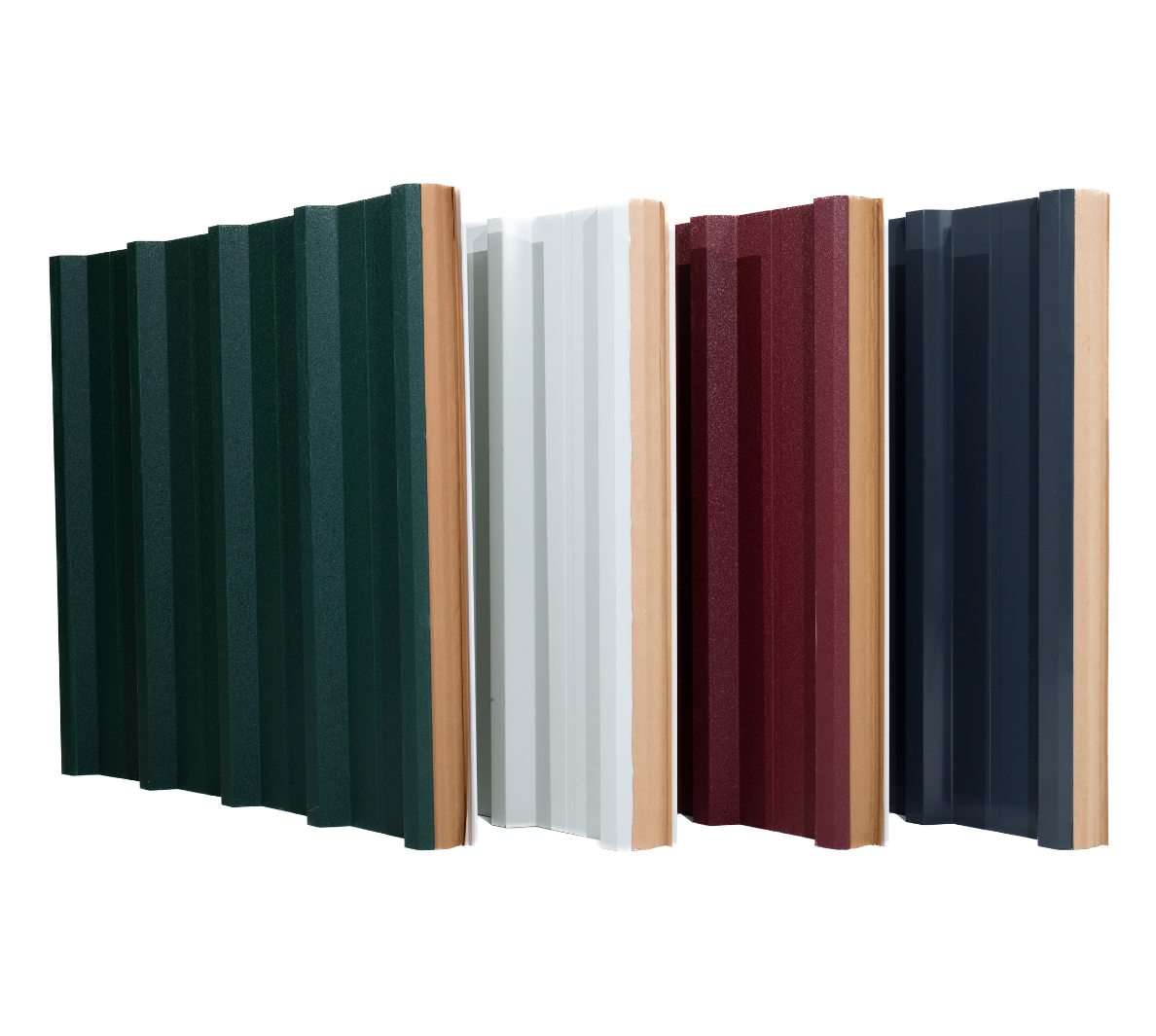

Polyurethane roof sandwich panel is a modern construction solution that combines durability, efficiency, and aesthetic appeal. This panel type represents a significant technological advancement in construction, offering a service life comparable to traditional building materials while being much lighter and more cost-effective.

Panex offers 5-hump roof sandwich panels (with a 4 cm hump height), making them an ideal roofing material for various types of commercial, public, and industrial buildings, including shopping centers, warehouses, sports halls, storage rooms, garages, booths, cold storage facilities, and more. These panels are also highly effective for building insulation.

Panex roof sandwich panels consist of three main layers:

1.The top layer is made of galvanized metal coated with primer and paint. This coating is resistant to corrosion, enhancing the material's longevity.

2. The core layer is made of polyurethane foam, which provides excellent thermal insulation, repels water, and has antibacterial properties. It also offers effective fire resistance, with chemical additives that help prevent fire and ensure high levels of safety.

3. The bottom layer is similar to the top layer, adding extra structural strength and durability. Panex uses painted galvanized sheet iron coils that meet ECCA quality standards.

Panex manufactures all the materials and components needed to build modern structures. In addition to roof and wall sandwich panels, we offer silicone curtains, isothermal doors, and a wide range of necessary accessories.

Technical characteristics

Advantages

Durability

In addition to their thermal insulation and fire resistance, roof sandwich panels are highly durable, withstanding various environmental conditions. The panels can maintain their original condition for many years.

Moisture Resistance

Roof sandwich panels are moisture-resistant, making them ideal for buildings located in damp environments or those that require controlled humidity.

Lightweight Construction

Roof sandwich panels are much lighter than traditional roofing materials like concrete or brick. In some cases, buildings can even be constructed without a foundation, further reducing the cost and complexity of construction.

Fire Resistance

Roof sandwich panels are made from fire-resistant materials, fully complying with fire safety standards. This makes them ideal for public, commercial, and residential buildings.

Cost-Effectiveness

Buildings covered with roof sandwich panels require no additional maintenance after installation, making them a highly economical option. The panels are pre-manufactured according to the customer’s exact specifications, eliminating the need for post-installation processing, which saves time and money.

Thermal Insulation

Roof sandwich panels provide excellent thermal insulation, helping reduce energy consumption for both heating and cooling. Buildings constructed with these panels maintain a consistently stable internal temperature, directly contributing to energy efficiency and cost savings.

Service process

Consultation & Planning

We calculate quantity of panels, thickness, and metal type of surface to fit your project precisely.

Production

We manufacture panels with advanced technology, ensuring quality and durability.

Pickup & Delivery Help

Pick up from our warehouse, or we help arrange delivery if needed.